Tie one hand behind your back and try to do an everyday task. Not easy right? For those with missing limbs, life can be challenging. But imagine being able to change a child’s life using 3-D printing. That’s exactly what a group of New Jersey high school students are aiming to do.

Printers have evolved massively from the original machines that were made up of sets of wooden blocks; it was deemed a huge success when the portable printer was born, and the publishing industry also saw a good deal of development with regard to equipment. For instance, binding a booklet used to be a manual process, but now we have a saddle stitch booklet maker maker that can make the process a lot easier and efficient. Besides the book print, now 3-D printing is taking the world by storm with its huge potential for not only technological development but also development in other fields like healthcare. For example, 3-D printing is perfect for creating affordable and usable prosthetics. And a surprising number of children need them. One in 1,000 infants are born with missing fingers, and others lose fingers and hands to injury. Each year, about 450 children receive amputations as a result of lawn mower accidents, according to a study in pediatrics.

Prosthetics are often hard to come by because they are expensive and children outgrow the prosthesis within years, or even months. Most children do without prosthetics, fighting to do with one hand what most of us do with two. Even if children are able to manage the expensive additions, they grow too quickly to make the investment practical. State-of-the-art prosthetic replacements are complicated medical devices, powered by batteries and electronic motors, and can cost thousands of dollars.

A dozen Hamilton, New Jersey students are determined to use their new 3-D printer, acquired by Steinert High School’s Innovation Lab, not just to learn about technology, but to help others.

“The Innovation Lab offers students unique opportunities to explore different technologies,” said Sharbel Skaff, a Steinert senior. “We wanted to see how we could use the 3-D printer to help the community.”

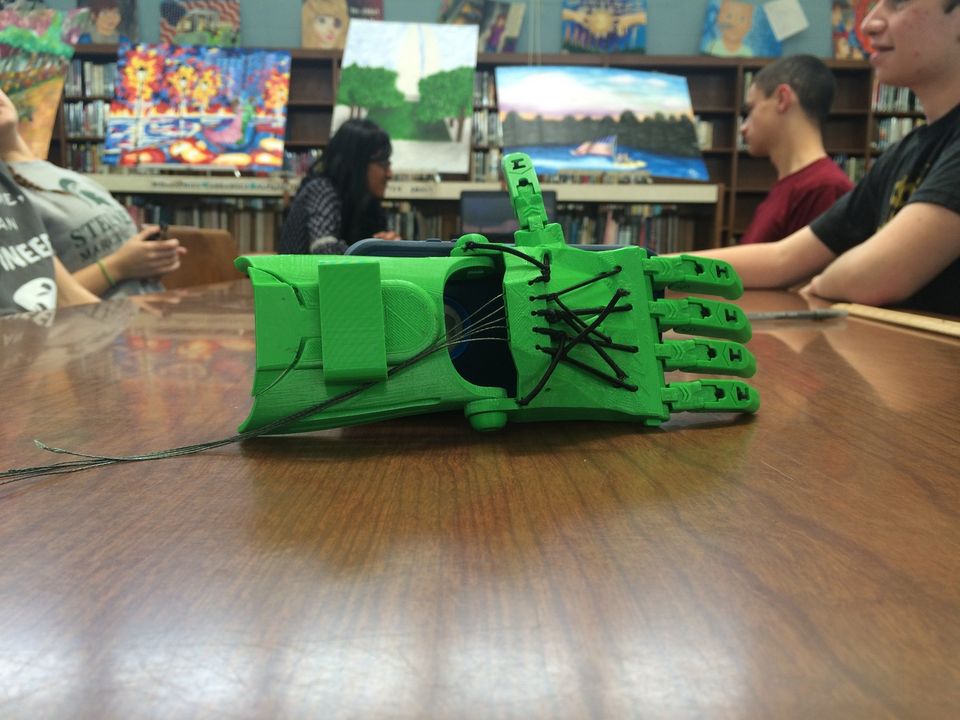

The Innovation Lab students completed work on their first prosthetic hand, completely built and assembled in the high school media center over dozens of lunch periods, club meetings and after-school sessions. The bright green hand (pictured above) is a basic model that could fit a toddler. Completion of the hand was the first step in receiving certification that will allow the club to create custom prosthetics for children across the world.

“To be able to provide a prosthetic device, and change a child’s life really brings home the kind of impact students can have using their technology, design and engineering classes,” said Steinert librarian Renée Rogers, the Innovation Lab’s supervisor. “Prosthetics that normally cost families thousands of dollars can now be printed and assembled by volunteers for less than $50. Our students really got behind this project, and raised all the money for the materials.”

During the winter months, the students used the 3-D printer to create custom Christmas ornaments which they sold in order to purchase hardware for the prosthetic hand, and as a way to get acquainted with the technology.

The Innovation Lab met at the library to thread wires between the hand’s knuckles. They passed the hand back and forth, some students focusing on threading the wires and others tightening and fastening. At one end of the table, a YouTube tutorial played as students pointed out the subtle differences between their model and the one on the laptop screen.

The hand started out simply as a collection of files downloaded from the Internet. From there, the students programmed the 3-D printer to create the different parts, routinely troubleshooting during the printing process. After a few failed attempts, Rogers noted, “The students are enjoying the real world application of everything they’re learning in their science, math and technology classes.”

Sandra Baskharon, a junior, took her interest in prosthetics a step further when she won the Mercer Science and Engineering Fair with another prosthetic hand project. That project used radio-frequency identification (RFID) tags to program the hand to perform functions such as grasping, pinching or counting fingers.

“It’s cool to help someone regain that kind of ability,” Baskharon said. “Everybody can use them.”

Newly-certified volunteers with eNABLE, an organization that matches volunteer builders and individuals in need of prosthetics, the Innovation Lab is now eagerly awaiting their first assignment.

“The students can’t wait until we’re connected with a child and doctor so they can really make a difference in someone’s life,” Rogers said.

The entire project also comes with a fundraising component. The 3-D printer was purchased following a crowdfunding campaign organized by Rogers on DonorsChoose.org, which qualified the project for a matching grant from the Bill and Melinda Gates Foundation.

What is your school doing to make a difference? Share your school’s innovative project with us in the comment section below.

Interested in 3-D printing and other innovative technologies that are making a difference in the world? TEDxNavesink Makers is the place for you. The event will be on April 9, 2016, at Monmouth University, and tickets are on sale now. Get them here.